The Power Of Systems Thinking

Image Credit: Unknown

“You never change things by fighting the existing reality.

To change something, build a new model that makes the existing model obsolete.”

― Buckminster Fuller

How Your Actions Impact Others: The Power of Systems Thinking

By Coach Larry Weber

A few years ago, I wrote an article about systems thinking — one of the most

important topics I’ve ever tackled — and yet, hardly anyone read it. People

tend to gravitate toward stories about people’s lives, struggles, and triumphs.

I love those stories too. But some lessons, though less flashy, are absolutely

life-changing if you take them to heart.

This is one of those lessons.

Why Systems Thinking Matters — Even If It Sounds Boring

Every team, family, classroom, or workplace is a system—a network of

interconnected parts. What happens in one part affects everything else.

It’s easy to think your job, your choices, or your role only impact you or your

small corner of the world. But that’s rarely true. Most of what we do ripples

downstream to others, whether we realize it or not.

When people don’t see the whole system, they often fix the wrong problem or

blame the wrong person. Sometimes, they even make things worse without

realizing it.

Let me show you what I mean.

The “Star Team” Story — When Appearances Mislead

In one organization I worked with, there was a team that everyone admired. They

were the “stars.” They hit record numbers, looked like heroes, and got all the

recognition.

Then there was another team — from the same company, working on the same project — but their numbers were

half as good. People whispered that maybe they weren’t working hard enough.

When we mapped the entire process — step by step from start to finish — we

discovered something eye-opening:

- The “star team” was taking the easiest tasks.

- The other team was handling the most complex and time-consuming work.

No one had realized it because the process wasn’t documented or tracked across

teams. The “stars” looked great on paper, but they were cherry-picking the

simple stuff.

Once we evened out the workload and removed unnecessary steps, the supposedly

“weak” team performed just as well — even better — than the star team.

If we hadn’t taken a systems view, innocent people would have been blamed,

maybe even fired, for something that wasn’t their fault.

What Happens When You Don’t See the System

Here’s the hard truth: most teams and organizations accidentally set themselves

up to fail because they operate in silos.

Each department, classroom, or training group focuses solely on its part, unaware of how its actions impact others. It’s like each part of an orchestra

playing their own song without listening to the conductor.

When this happens:

- One decision in “Team A” can double the workload for “Team B.”

- A shortcut taken upstream can cause chaos downstream.

- A small communication gap can cause someone else tremendous stress, frustration, or

even harm.

It’s Not Just True at Work — It’s True in Life

These same principles also apply to everyday life.

- When a teacher or administrator forgets to communicate a schedule change to a

coach, an athlete might miss practice and lose fitness without understanding

why their performance is suddenly slipping.

- When we fail to plan, we rush out the door, forget our gear for practice, and

start the day stressed — setting off a ripple that affects everyone around us.

- When a runner skips recovery days or adds extra workouts without talking to

the coach, it doesn’t just impact that athlete — it affects the whole team.

They can’t contribute at their best because one weak link in the chain affects

everyone downstream.

A Personal Example That Still Drives Me

One of the most painful experiences of my life was losing my nephew. Some of

the root causes of his death were poor handoffs between departments — unclear

communication and broken processes.

Silo A was unaware of what Silo B was doing. One team assumed another would

handle a task. No one saw the whole picture.

The system failed him.

That experience is why I am so passionate about teaching this. I’ve seen what

happens when the left hand doesn’t know what the right hand is doing — in

hospitals, schools, businesses, and even youth sports.

When systems are broken, good people pay the price.

Every Decision Has a Ripple Effect

Before you make a decision — big or small — ask yourself:

- Who will this affect downstream?

- What could go wrong if I don’t communicate this change?

- How can I make this easier, not harder, for the next person in line?

Here’s a simple way to apply this thinking in your daily life:

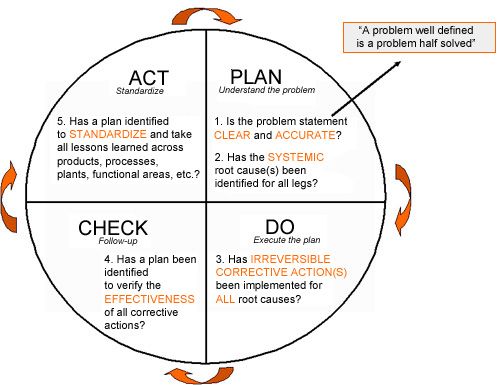

1. Map the flow. Write down the steps of a process — even a simple one. You’ll

be amazed at what you learn.

2. List the people impacted. Who depends on you? Who depends on them?

3. Ask for feedback. Before finalizing a decision, ask, “How does this impact

you?”

4. Fix the process, not the blame. When something goes wrong, resist

the urge to finger-point. Look at how the system allowed the problem to happen.

Easy-to-See Everyday Examples

- In sports: A coach changes the training plan without telling the trainer. The

athletes show up sore and underperform. Communication fixes that.

- In business: A salesperson promises a delivery date before checking with

production. Production scrambles, stress rises, and quality drops.

- At home: Someone forgets to refill the gas tank. The next driver is late for

work. One small action — or lack of it — rippled through the day.

- In a church or nonprofit: A volunteer doesn’t know their task because no one

explained the larger plan. People get frustrated, and good intentions fall

flat.

Each of these small breakdowns adds up. Each one affects others downstream.

The Golden Rule of Systems Thinking

Jesus said in Matthew 7:12,

“In everything do to others as you would have them do to you.”

That’s not just a moral principle — it’s a systems principle.

If you build a process, communicate, and plan with others in mind, everything

runs smoothly. Efficiency improves. Stress drops. People feel seen and valued.

Doing for others what you’d want done for you is at the heart of systems

thinking. It’s love in motion.

Final Thoughts: Building Championship Systems

Whether you’re running a business, coaching a team, leading a family, or

serving in your community, systems thinking can make a profound difference.

When people see how their actions connect, blame disappears and collaboration

begins.

Great teams and organizations don’t happen by accident. They plan, document,

communicate, and keep improving together.

You’ll reach your God-given potential when you sweat the details in planning,

check your ego at the door, and care about the people affected by your

decisions.

That’s how championships are built.

That’s how lives are changed.

That’s how love shows up in action.

Blessings,

Coach Weber

Philippians 4:13

The road to any championship in life requires transparency, reviewing and improving systems, and a commitment to always getting better. Finding the root causes of challenges that stand in the way of your next breakthrough is essential to success.

Systems thinking and process improvement projects are the tools that help you reach the next level, whether you are a billion-dollar corporation or a small non-profit just trying to survive.

Image Credit: Kaleidico

Image Credit: Campaign Creators